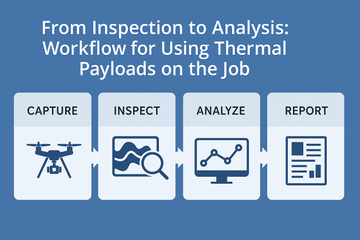

In industries like energy, utilities, and infrastructure, thermal imaging has become a critical tool for identifying problems before they escalate. With drones equipped with payloads like the DJI Zenmuse H20T, professionals can inspect assets quickly, safely, and cost-effectively. But collecting thermal data is only the first step—the real value comes from turning it into actionable insights.

Step 1: Plan the Inspection

-

Define objectives: Are you looking for overheating electrical components, insulation leaks, or structural weaknesses?

-

Set parameters: Establish flight paths, altitude, and camera settings to ensure consistent data.

-

Safety first: Confirm regulatory compliance and site safety before deployment.

Step 2: Capture Thermal Data

-

Use the Zenmuse H20T to capture both visual and thermal imagery in real time.

-

Look for temperature anomalies: hotspots, cold spots, or irregular heat signatures.

-

Ensure environmental conditions (time of day, ambient temperature) are considered to avoid misleading results.

Step 3: Analyze Thermal Images

-

Import the data into analysis software like DJI Thermal Analysis Tool (TA) or third-party platforms.

-

Compare suspected anomalies against baseline readings.

-

Classify findings: minor issue, urgent repair, or routine monitoring.

Step 4: Create Actionable Reports

-

Generate clear, annotated reports combining thermal and visual data.

-

Highlight severity levels and recommended actions.

-

Share findings with stakeholders for informed decision-making.

Step 5: Follow-Up & Continuous Monitoring

-

Schedule follow-up inspections to track changes over time.

-

Use trend analysis to predict potential failures before they occur.

-

Build a maintenance schedule based on real data, not guesswork.

Conclusion

Thermal payloads transform inspections from reactive to proactive. By following a structured workflow—from planning and capturing data to analysis and reporting—companies can reduce downtime, improve safety, and save costs. The result is not just better inspections, but smarter asset management.

#DroneInspection #ThermalImaging #DJIEnterprise #ZenmuseH20T #EnergyIndustry #InfrastructureSafety #SmartMaintenance #DroneTechnology