Introduction

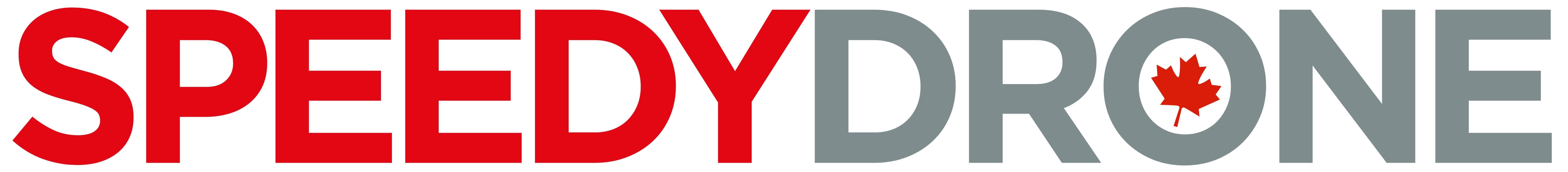

Industrial inspections often require drones to operate in tight, cluttered, and hazardous environments—from flying near high-voltage power lines to navigating around pipelines and towers. Traditional obstacle avoidance sensors struggle with small or thin objects, posing serious risks.

The DJI Matrice 4D Series solves this with a dual sensing system that combines rotating LiDAR with millimeter-wave radar, enabling it to see what other drones cannot. This technology is engineered for safer, more reliable flights in demanding industrial operations.

Rotating LiDAR: 360° Precision Mapping

-

Provides high-resolution, real-time 3D mapping of the surrounding environment.

-

Detects obstacles in all directions, creating a dynamic safety bubble around the drone.

-

Adapts to varying lighting conditions, maintaining accuracy even in low-light or glare-heavy settings.

👉 Example: Inspecting refinery towers where reflective metal surfaces would confuse standard vision sensors.

Millimeter-Wave Radar: Seeing the Invisible

-

Sensitive enough to detect thin, low-profile objects like power lines, antenna cables, and wires.

-

Penetrates dust, fog, rain, and smoke, ensuring obstacle detection in harsh weather.

-

Complements LiDAR by filling in blind spots or environmental conditions where lasers alone might falter.

👉 Example: Power line inspections where detecting a single cable is mission-critical.

Why This Matters for Industrial Environments

1. Power Line and Grid Inspections

-

Traditional sensors often miss thin conductors.

-

The Matrice 4D’s dual system ensures accurate detection, preventing collisions and outages.

2. Oil, Gas, and Pipeline Facilities

-

Detects metal frameworks, pipes, and support structures in congested layouts.

-

Operates safely in dusty or smoky environments where vision sensors may fail.

3. Construction and Mining Sites

-

Navigates around cranes, scaffolding, and machinery.

-

Improves safety for autonomous or semi-autonomous flight modes.

4. Nighttime and Low-Visibility Missions

-

Combined LiDAR + radar ensure consistent performance in low-light, rain, or fog, expanding operational windows.

Safety Benefits

-

Collision Prevention: Detects objects large and small, visible and thin.

-

Operational Continuity: Enables missions in weather or environments that would ground other drones.

-

Worker Safety: Reduces need for manual inspections near dangerous equipment.

-

Data Accuracy: Stable, collision-free flights ensure consistent inspection imagery.

Conclusion

The DJI Matrice 4D Series sets a new benchmark for drone safety in industrial environments. Its rotating LiDAR and millimeter-wave radar combination provides unparalleled obstacle avoidance, capable of detecting even thin objects like power lines. For industries where accuracy and reliability are critical, this technology ensures missions are not only efficient—but also safe.

#DJIMatrice4D #DroneSafety #ObstacleAvoidance #LiDAR #RadarTech #IndustrialDrones #InfrastructureInspection #PowerLineInspection #EnterpriseDrones #DJIEnterprise